Introduction to a Circular Economy framework

Governments, industries, and communities increasingly acknowledge that the linear ‘take-make-waste’ approach to development and economic growth is not sustainable.

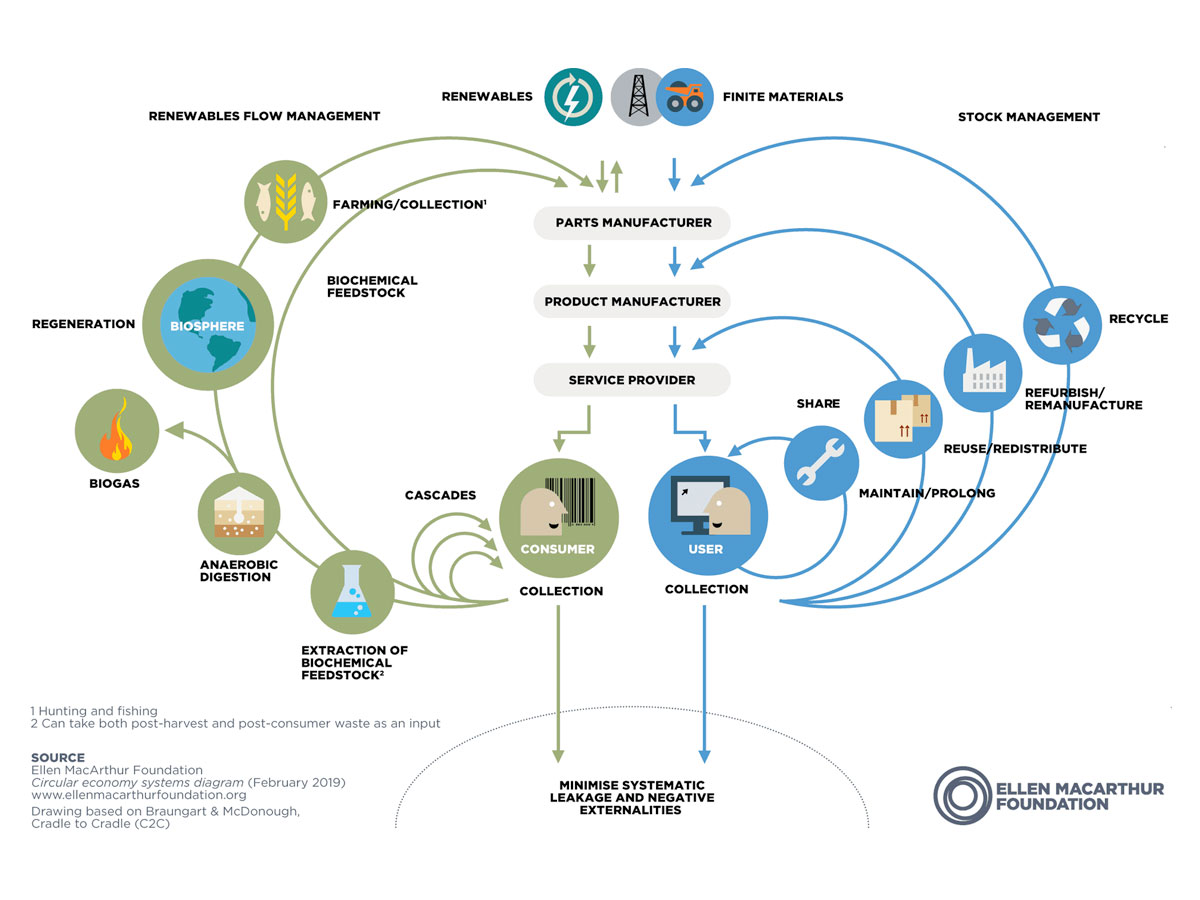

In response, industries and many levels of Government have committed to Circular Economy principles for economic development. Driven by design, a Circular Economy aims to: eliminate waste and pollution; keep products and materials in their highest order use; and regenerate natural systems.

A Circular Economy model goes beyond waste management by aiming to maximise the reuse, refurbishment, and recycling of materials, as well as redesign of manufacturing, to reduce waste. Commitment to a Circular Economy can support the development of new industries and jobs, reduce emissions, and increase the efficient use of natural resources (including energy, water and materials). Circular Economy concepts are linked to Sustainable Development Goals[1]. Figure 1 provides a diagrammatic example of how a Circular Economy could operate.

Figure 1: Outline for a Circular Economy

Image sourced from the Ellen Macarthur Foundation

Australia’s National Waste Strategy

In 2018, Australia’s National Waste Policy[2] was released following consultation and collaboration with State and Territory governments and the Local Government Association.

The policy adopted five initiatives to underpin waste management, recycling and resource recovery in a Circular Economy:

- Avoid waste:

-

- Prioritise waste avoidance, encourage efficient use, reuse and repair.

- Design products so waste is minimised, they are manufactured to last and materials can be more readily recovered.

- Improve resource recovery:

- Improve material collection systems and processes for recycling.

- Improve the quality of recycled material produced.

- Increase use of recycled material and build demand and markets for recycled products.

- Better manage material flows to benefit human health, the environment, and the economy.

- Improve information to support innovation, guide investment, and enable informed consumer decisions.

These five initiatives support the waste hierarchy represented in Figure 2.

Figure 2: Waste Hierarchy

Resource Recovery Parks and Energy from Waste

Resource Recovery Parks (RRPs) (also known as Material Recovery Centres, Parks or Precincts) are central to achieving Circular Economy policy outcomes. Incoming waste is sorted and treated to maximise the useful life and value of material through re-use, recycling and upcycling.

The various material streams can be used in an existing manufacturing process or by micro- or small-scale manufacturers who apply innovative technology, material science and engineering to create new products.

An Energy from Waste (EfW) facility located within the RRP can then provide the end-of-life treatment of waste, virtually eliminating household and commercial & industrial waste going to landfill.

Companies located within, or proximate to, the RRP can access quality recyclates to replace virgin raw materials in their manufacturing process and take advantage of electricity, steam and hot water produced by the EW facility.

Potential manufacturing and industrial activities that could be co-located with the RRP include:

- In vessel composting or anaerobic digestion of organic material,

- Black soldier fly biowaste treatment to produce protein and chitin,

- Thermal treatment and recovery of energy from waste,

- Processing fly ash to produce cinder blocks and pavers,

- Processing bottom ash to recover the metals and produce a construction aggregate

- Reprocessing of electronic goods including gold extraction,

- Tyre recovery and shredding or reprocessing,

- Biofuel production,

- Oil and petrochemical recovery from plastics and tyres,

- Plastics to artificial wood,

- Hydrogen production,

- Electrical storage using batteries,

- Electric vehicle charging points, and

- Manufacturing using new materials science such as thermal insulation using fly ash and waste glass.

Figure 3 is a material flows diagram that illustrates how material streams, sorted in a RRP, can be used to support Circular Economy policy outcomes.

Figure 3: Indicative waste material flows

Eco – Industrial Parks

A modern Resource Recovery Park with an Energy from Waste facility for end-of-life treatment of waste should be part of a portfolio of initiatives to achieve Circular Economy objectives. An industrial park that creates a manufacturing ecosystem around the RRP/EfW processing of waste has potential to deliver better utilisation of waste as well as better economic, development and environmental outcomes.

How that industrial park operates can improve both Circular Economy objectives and achievement of Sustainable Development Goals.

In January 2021, the United National Industrial Development Organisation (UNIDO), the World Bank Group (WBG) and Deutsche Gesellschaft für Internationale Zusammenarbeit (GTZ) published “An International Framework of Eco-Industrial Parks Version 2.0”[3]. The framework guides policymakers and practitioners on the critical elements that will help both governments and the private sector work together in establishing economically, socially and environmentally sustainable industrial parks.

From the report:

“An important element of the Eco-Industrial Park approach is to create a more sustainable operating environment for firms, and to promote competitiveness and job creation. These Eco-Industrial Parks should be designed to use resources more efficiently and improve productivity. They should provide investors with environments specifically adapted to support the achievement of their social responsibility goals. They should also increase market access to sustainable products, and lower exposure to climate change risks. Additionally, Eco-Industrial Parks will contribute to the attainment of the Paris Climate Change Accord’s Nationally Determined Contributions at the country level”.

An EIP is a community of businesses located on a common property in which businesses seek to achieve enhanced environmental, economic and social performance through collaboration in managing environmental and resource issues. This is known as industrial symbiosis, which is a means by which companies can gain competitive advantage through the physical exchange of materials, energy, water and by-products, thereby fostering inclusive and sustainable development#4.

EIPs operate on principals of continuous improvement with monitoring to improve performance and outcomes. Figure 4 summarises key performance areas that are monitored in EIPs and reported to stakeholders. With the provision of cost effective and reliable energy such a draw for companies this will increase the value of the overall development to the developer.

Figure 4: Key areas for performance monitoring of Eco-industrial Parks

Final thoughts

Transitioning to a Circular Economy where waste is eliminated, resources are circulated, and nature is regenerated requires a major shift away from the existing approach to economic activity and growth.

The starting point is to commit to diverting all household and commercial & industrial waste from landfill and treat waste as a resource. A purpose-built RRP and EfW Facility can be the foundation of a manufacturing hub that operates on EIP principles.

The ability to provide raw materials (sorted waste streams) and cheap reliable base-load power and energy will be a significant drawcard for companies to locate within the EIP. Locating the EIP outside Australia’s capital cities supports regional strategies for quality investment, sustainable development and job creation; eases pressure on urban housing and infrastructure; and takes vehicles off roads.

Perhaps most importantly, development of sustainable RRP/EfW facilities can quickly help solve Australia’s mounting waste problems.

[2] https://www.environment.gov.au/system/files/resources/d523f4e9-d958-466b-9fd1-3b7d6283f006/files/national-waste-policy-2018.pdf

[3] https://www.unido.org/sites/default/files/files/2021-04/An%20international%20framework%20for%20eco-industrial%20parks%20v2.0.pdf

[4] https://www.unido.org/our-focus-safeguarding-environment-resource-efficient-and-low-carbon-industrial-production/eco-industrial-parks